Why Optical Measurement Solutions Are Essential for Modern Production Practices

In today's competitive manufacturing landscape, you can not afford to ignore the benefits of optical measurement systems. These innovations enhance precision and rate in high quality control, lowering human error that might bring about costly flaws. By incorporating advanced laser and imaging methods, you'll simplify procedures and improve product quality. Exactly how precisely do these systems transform producing techniques, and what effects do they hold for the future?

The Advancement of Optical Dimension Equipments in Production

As modern technology swiftly breakthroughs, the advancement of optical dimension systems in production has actually changed how industries guarantee accuracy and top quality. You could've seen that typical dimension methods, like micrometers and calipers, commonly fall short in speed and precision. Optical systems become an option, leveraging light to catch comprehensive measurements promptly.

In the past, these systems were restricted, mostly utilized for specific applications. Now, innovations in laser innovation and imaging software permit for flexible, real-time assessments throughout various fields. You can anticipate higher precision and reduced human mistake when executing these systems in your procedures.

Additionally, the integration of automated optical assessment tools simplifies top quality control, letting you concentrate on production effectiveness. As the need for precision grows, adjusting to these innovative optical dimension modern technologies will maintain your procedures dependable and affordable in a hectic market.

Trick Advantages of Optical Measurement Technologies

Optical dimension modern technologies provide a number of vital advantages that can significantly boost your production processes. They provide high precision and accuracy, enabling you to make essential adjustments with confidence. This results in improved product high quality and decreased waste, which straight influences your profits.

Additionally, these systems are non-contact, meaning you can measure delicate or moving components without causing damage. This capability not only protects your materials but also increases throughput since you can measure items on the manufacturing line without disturbance.

Optical systems are often faster than traditional methods, allowing you to collect data rapidly and make timely choices. Their convenience suggests they can be used to a variety of geometries and products, adjusting quickly to your specific demands. By incorporating optical measurement technologies, you're not just staying on top of sector criteria; you're setting them.

Applications of Optical Dimension in Numerous Industries

While numerous industries are significantly turning to advanced dimension methods, the applications of optical measurement systems stick out because of their unique capacities. In automobile production, you'll discover these systems helping to assure accurate placement and surface top quality in elements. In aerospace, they're essential for evaluating complex geometries and assuring the safety of essential components.

In electronic devices, optical measurement help in the accurate positioning of integrated circuits on circuit boards, improving total effectiveness. The clinical device market additionally benefits, as these systems enable for the thorough measurement of complex parts, assuring they satisfy stringent regulative requirements.

Optical dimension systems are also utilized in fabrics, where they assess fabric patterns and flaws, boosting top quality. With their convenience, these systems are revolutionizing exactly how numerous sectors approach dimension, inevitably driving innovation and efficiency in production processes.

Enhancing Quality Assurance Via Optical Dimension

When it comes to quality assurance, precision measurement techniques can make all the difference in your manufacturing process. By executing optical measurement systems, you can accomplish real-time high quality guarantee that keeps your products trusted and regular. This not just boosts your total manufacturing effectiveness however likewise increases client fulfillment.

Accuracy Measurement Techniques

In today's competitive production landscape, carrying out precision measurement techniques can greatly boost top quality control procedures. By using advanced optical dimension systems, you can attain higher accuracy and repeatability in your dimensions. These methods allow you to detect also the tiniest variations in item measurements, guaranteeing that every component fulfills rigid specifications.

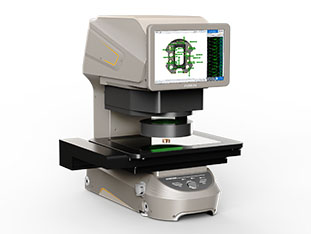

Making use of devices like laser scanners and optical comparators, you can rapidly analyze the quality of your items, significantly reducing the danger of problems. These systems offer real-time information, enabling you to change procedures right away, thereby lessening waste.

Incorporating these accuracy dimension techniques not just improves product top quality but likewise enhances customer complete satisfaction and self-confidence in your brand. Welcome these developments to keep a competitive edge in your production procedures.

Real-Time Quality Control

Optical measurement systems play a crucial duty in this procedure, allowing you to keep track of item top quality continually. By integrating these systems into your workflow, you can find inconsistencies from specs virtually instantly, decreasing the possibilities of flaws getting to the market. Inevitably, welcoming real-time top quality guarantee with optical dimension systems not just enhances your result yet additionally reinforces consumer trust fund in your brand name.

Lowering Waste and Improving Performance With Optical Equipments

When you carry out optical dimension systems, you'll see a considerable reduction in production errors. These systems simplify top quality control procedures, making it simpler to determine and deal with issues promptly. Consequently, you not just minimize waste but additionally boost general efficiency in your production procedures.

Decreasing Production Errors

To reduce production errors properly, suppliers significantly depend on optical measurement systems that enhance accuracy and lower waste. By making use of exact measurements, you can guarantee that every part fulfills specs, which look at these guys significantly reduces the threat of defects. As you accept optical measurement systems, you'll see a significant decrease in rework and scrap prices, inevitably leading to much more efficient production methods and improved fundamental results.

Streamlining Quality Assurance

By embracing optical dimension systems, you're not just minimizing manufacturing errors yet likewise streamlining top quality control. These systems offer real-time responses, enabling you to detect flaws before they rise. Instead of depending on manual assessments, which can be lengthy and vulnerable to human error, you can automate the procedure. This accelerate production and warranties consistency across sets. With accurate dimensions, you can recognize variations in products or procedures promptly, decreasing waste and boosting total efficiency. Furthermore, incorporating optical systems helps you preserve conformity with sector standards, providing you an affordable side. Ultimately, investing in optical measurement modern technology boosts your quality control, causing far better items and satisfied customers.

Integrating Optical Measurement Equipments Into Existing Procedures

Next, choose the best optical dimension modern technology that straightens with your production needs. Think about aspects like the dimension of the elements, called for accuracy, and assimilation capacities with existing tools. Educating your team on the brand-new modern technology is important; they need to feel confident using it to maximize its advantages.

Ultimately, monitor the integration process very closely. Accumulate information on performance improvements and identify any kind of obstacles early on. This aggressive method guarantees not only a smooth shift but likewise a lasting influence on your manufacturing performance and product top quality.

The Future of Optical Dimension in Production

As you embrace optical measurement systems in your production procedures, it's important to look in advance and think about just how these innovations will certainly develop. Future advancements promise boosted accuracy and rate, enabling real-time responses that can substantially reduce production mistakes (optical measurement systems).

Additionally, miniaturization of optical sensors will make them a lot more flexible, suitable right into tighter rooms and various applications. The rise of automation will certainly also boost their capabilities, as automated systems will utilize these measurements to maximize manufacturing circulations seamlessly.

As you adjust to these adjustments, remaining notified regarding arising modern technologies will certainly be necessary. By investing in innovative optical dimension remedies, you'll position your manufacturing operations for long-lasting success and effectiveness. Accept the future; it's intense review for those that introduce!

Regularly Asked Questions

How Do Optical Measurement Solutions Compare to Traditional Dimension Approaches?

Optical dimension systems provide higher rate, precision, and effectiveness compared to standard techniques - optical measurement. You'll locate they minimize human mistake and enhance information collection, making your dimensions extra reliable and improving total performance in your procedures

What Are the First Prices of Implementing Optical Measurement Solutions?

You'll discover the first expenses of applying optical measurement systems can be significant, frequently involving devices training, software application, and purchase. These investments normally lead to greater effectiveness and precision in the long run.

Are There Details Training Requirements for Making Use Of Optical Dimension Systems?

Yes, you'll need details training to utilize optical dimension systems effectively. Familiarizing yourself with the tools, measurement, and software application strategies is essential. Producers often offer training programs to ensure you're skilled and positive in operation these systems.

Can Optical Dimension Solutions Be Personalized for Distinct Production Demands?

Yes, you can tailor optical dimension systems to fulfill your details production requirements. By changing specifications and integrating distinct features, these systems can enhance precision, performance, and flexibility, ensuring they line up perfectly with your manufacturing demands.

What Maintenance Is Needed for Optical Dimension Solutions?

You'll need to routinely clean the optics, adjust the system, and examine for software application updates. Keeping an eye on performance and resolving any type of wear or tear quickly assures your optical dimension systems function accurately and accurately in time.

Conclusion

In today's busy manufacturing globe, embracing optical dimension systems is vital for remaining competitive. These technologies not just enhance precision and rate however additionally improve quality assurance and decrease waste. By incorporating these sophisticated solutions into your procedures, you'll foster a society of integrity and client satisfaction. As you seek to the future, buying optical measurement will ensure your procedures remain reliable and certified, placing your business for ongoing success in the ever-evolving landscape.

As modern technology rapidly advancements, the development of optical measurement systems in manufacturing has actually changed how industries guarantee precision and high quality.While numerous markets are significantly transforming to innovative measurement techniques, the applications of optical measurement systems stand out due to their distinct capabilities. By utilizing advanced optical measurement systems, you can achieve higher precision and repeatability in your measurements. Optical measurement systems play a crucial function in this process, allowing you to monitor product top quality continually. Just How Do Optical Dimension Systems Contrast to Typical Dimension Techniques?

Comments on “Choosing the best optical measurement method for your use case”